Manufacturing process

Each step of our manufacturing process and our patented technology allows us to treat your products and provide support for your requests, under high-control environment, from the reception of vials through to their final packaging.

How it works

The manufacturing steps of Pyrofree® Vials

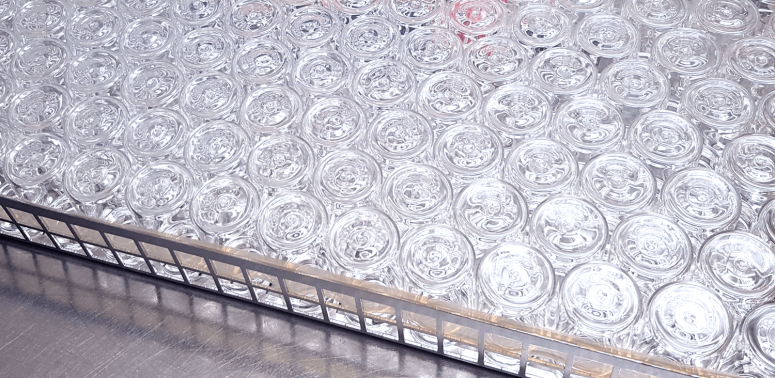

Preparation step

Vials are received, checked, tested and identified. Then, vials are placed in the basket upside-down.

Washing step

Vials are washed using STEELCO washing machine feed with Water For Injection (On site water loop) and dried.

Primary packaging step

Vials are packed under vaccum in a double PEEK pouches resisting over 300°C heat.

This step takes place in a Class B environment under laminar air flow.

Depyrogenation step

Vials are placed in oven for dry heat depyrogenation.

Final packaging step

Overwrapping of the double PEEK bags with PA/EvOH/PE bag under vaccum and packages are placed in cardboard box.